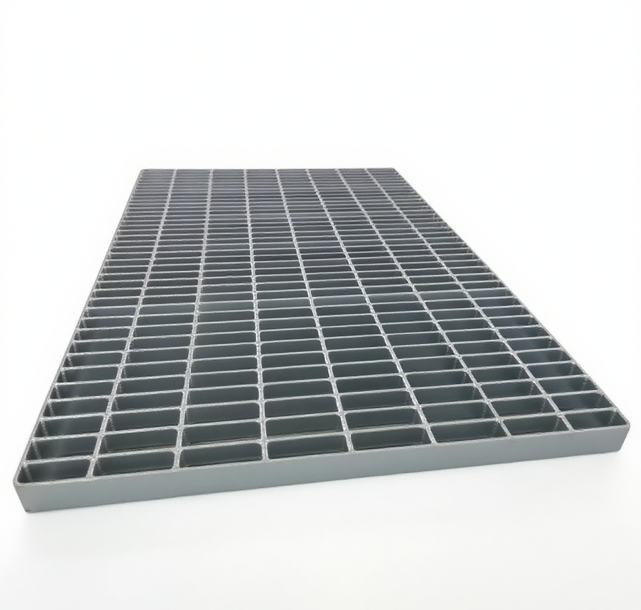

Different Surface Treatment Options for Anti-Slip Toothed Steel Grating

Anti-slip toothed steel grating is a critical component widely used in industrial plants、transportation hubs、offshore platforms、stair treads and public areas where slip resistance is paramount. Its toothed surface structure inherently enhances friction, but proper surface treatment is essential to amplify its anti-slip performance、extend service life、resist corrosion and adapt to diverse harsh environments. The choice of surface treatment depends on factors such as application environment、corrosion intensity、 maintenance requirements and budget constraints.

1. Hot-Dip Galvanizing (HDG)

Hot-dip galvanizing is the most commonly used surface treatment method for anti-slip toothed steel grating, favored for its excellent corrosion resistance and cost-effectiveness. The process involves immersing the pre-cleaned (degreased、pickled and fluxed) steel grating into a molten zinc bath (typically at 440–460°C), forming a metallurgical bond between the zinc and the base steel. This results in a uniform, dense zinc coating that acts as a physical barrier against moisture、oxygen and corrosive substances.

For anti-slip toothed steel grating, hot-dip galvanizing offers several key advantages. First, the zinc coating penetrates the gaps between the toothed bars and the bearing bars, ensuring full coverage even in hard-to-reach areas, which is crucial for maintaining anti-slip performance—any uncoated spots could become corrosion points and reduce friction over time. Second, the coating has high adhesion and wear resistance, able to withstand the frequent foot traffic or heavy load impacts typical of grating applications without peeling. Third, hot-dip galvanizing provides long-term protection, with a service life of 20–50 years in moderate environments (such as urban outdoor areas) and 10–20 years in harsher environments (such as near coastal areas with salt spray).

However, hot-dip galvanizing also has limitations. The high-temperature process may cause slight deformation of the toothed structure, though this is usually minimal and does not significantly affect anti-slip performance if controlled properly. Additionally, the zinc coating has a relatively smooth surface compared to other treatments, which may slightly reduce friction in extremely wet or oily conditions. It is also not suitable for environments with high concentrations of acids or alkalis, as these substances can accelerate zinc corrosion.

Typical applications of hot-dip galvanized anti-slip toothed steel grating include outdoor staircases, parking lot ramps, industrial walkways, and coastal piers (in moderate salt spray areas).

2. Powder Coating

Powder coating is a dry finishing process that involves applying electrostatically charged powder (composed of resin, pigments, and additives) to the surface of anti-slip toothed steel grating, followed by curing in an oven to form a hard, uniform coating. This method is known for its versatility in color, durability, and environmental friendliness (as it produces no volatile organic compounds, VOCs).

For anti-slip applications, powder coating can be customized to enhance friction by adding anti-slip additives (such as aluminum oxide, silicon carbide, or quartz sand) to the powder mixture. These additives create a textured surface that significantly improves grip, even in wet or oily conditions—making it ideal for areas where both anti-slip performance and aesthetics are important. Powder coating also provides excellent corrosion resistance, as the cured coating forms a seamless barrier that prevents moisture and corrosive agents from reaching the base steel. Additionally, it is highly resistant to chipping, scratching, and fading, ensuring long-term performance with minimal maintenance.

The main limitations of powder coating are its higher cost compared to hot-dip galvanizing and its reduced durability in extremely high-temperature environments (above 200°C), as the coating may degrade or discolor. It also requires careful surface preparation to ensure adhesion; any contaminants on the steel surface can cause the coating to peel or bubble. Furthermore, the powder coating may wear down more quickly in areas with extremely heavy foot traffic or abrasive contact, though this can be mitigated by choosing a thicker coating or a more wear-resistant powder formulation.

Powder-coated anti-slip toothed steel grating is commonly used in commercial buildings, shopping malls, hospitals, food processing plants (where hygiene and easy cleaning are required), and indoor industrial areas where corrosion is moderate.

3. Epoxy Coating

Epoxy coating is a liquid-based coating that consists of epoxy resin and a hardener, which react chemically to form a tough, adhesive film on the surface of the steel grating. It is widely used in environments with high corrosion resistance requirements, particularly in chemical plants, wastewater treatment facilities, and areas exposed to acids, alkalis, or solvents.

For anti-slip toothed steel grating, epoxy coating can be modified with anti-slip aggregates (similar to powder coating) to create a high-friction surface. The epoxy resin has excellent adhesion to steel, forming a strong bond that resists peeling and chipping, even under heavy use. It also provides superior chemical resistance compared to hot-dip galvanizing and powder coating, able to withstand exposure to harsh chemicals without degradation. Additionally, epoxy coatings are available in a range of thicknesses, allowing for customization based on the level of protection required—thicker coatings offer enhanced corrosion resistance and durability.

One of the main drawbacks of epoxy coating is its relatively short service life in outdoor environments, as prolonged exposure to ultraviolet (UV) radiation can cause the coating to yellow, become brittle, and crack over time. It is also more labor-intensive to apply than hot-dip galvanizing, requiring careful surface preparation (including sandblasting) and multiple coats to achieve the desired thickness. Furthermore, epoxy coatings are not suitable for high-temperature environments (above 120°C), as they may soften or decompose.

Epoxy-coated anti-slip toothed steel grating is primarily used in indoor or shaded industrial areas, such as chemical processing plants, wastewater treatment tanks, pharmaceutical facilities, and areas where exposure to harsh chemicals is common.

4. Zinc Plating (Electroplating)

Zinc plating, also known as electroplating, is a process that uses an electric current to deposit a thin layer of zinc onto the surface of anti-slip toothed steel grating. Unlike hot-dip galvanizing, which forms a metallurgical bond, zinc plating creates an electrolytic bond between the zinc and the base steel. The coating thickness is typically much thinner (5–25 μm) than hot-dip galvanizing (80–150 μm), making it a more cost-effective option for light-duty applications.

Zinc plating provides basic corrosion protection by acting as a sacrificial anode—zinc corrodes preferentially to steel, protecting the base metal from rust. For anti-slip toothed steel grating, zinc plating offers a smooth, uniform surface that does not significantly alter the toothed structure, ensuring that the inherent anti-slip performance is maintained. It is also available in various finishes, such as bright zinc, matte zinc, or passivated zinc (which enhances corrosion resistance further by adding a thin chromate or trivalent passivation layer).

However, the thin coating thickness means that zinc plating offers less corrosion resistance than hot-dip galvanizing or epoxy coating, making it unsuitable for harsh environments (such as coastal areas, chemical plants, or outdoor areas with heavy rainfall). The coating is also more prone to wear and peeling in high-traffic areas, requiring more frequent maintenance or re-plating.

Zinc-plated anti-slip toothed steel grating is commonly used in light-duty indoor applications, such as office buildings, residential staircases, and small-scale industrial facilities where corrosion is minimal.

5. Phosphating Treatment

Phosphating treatment is a chemical surface treatment that forms a thin, porous phosphate film on the surface of anti-slip toothed steel grating. The process involves immersing the steel grating in a phosphating solution (typically composed of phosphoric acid and metal salts), which reacts with the steel to form a layer of iron phosphate, zinc phosphate, or manganese phosphate. Unlike other coatings, phosphating is not primarily used for corrosion protection alone; instead, it is often used as a pre-treatment for other coatings (such as powder coating or epoxy coating) to improve adhesion.

For anti-slip toothed steel grating, phosphating treatment can enhance the anti-slip performance slightly by creating a rough, porous surface that increases friction. However, its main benefit is its ability to improve the adhesion of subsequent coatings— the porous phosphate film acts as a "mechanical anchor" for the coating, preventing peeling and ensuring long-term durability. Phosphating also provides some basic corrosion protection, though it is not sufficient for harsh environments when used alone.

The limitations of phosphating treatment are that it offers minimal corrosion protection on its own and requires additional coatings for long-term durability. The phosphate film is also relatively thin and brittle, making it prone to wear and damage if not covered by a topcoat. Additionally, the phosphating process produces chemical waste that requires proper treatment, increasing environmental costs.

Phosphating treatment is almost always used as a pre-treatment for anti-slip toothed steel grating that will be further coated with powder coating or epoxy coating, particularly in industrial applications where high adhesion and durability are required.

6. Conclusion

The choice of surface treatment for anti-slip toothed steel grating is critical to ensuring its performance, durability, and suitability for the intended application. Hot-dip galvanizing remains the most popular option for its balance of cost-effectiveness and corrosion resistance, making it ideal for most outdoor and moderate industrial applications. Powder coating offers versatility in color and enhanced anti-slip performance, suitable for commercial and indoor industrial areas where aesthetics and grip are important. Epoxy coating provides superior chemical resistance, making it the preferred choice for harsh chemical environments. Zinc plating is a cost-effective option for light-duty indoor applications, while phosphating treatment is primarily used as a pre-treatment to improve coating adhesion.

When selecting a surface treatment, it is important to consider the application environment (corrosion intensity, temperature, UV exposure), usage requirements (foot traffic, load capacity, anti-slip needs), maintenance budget, and aesthetic preferences. By choosing the right surface treatment, anti-slip toothed steel grating can provide reliable slip resistance and long-term durability, ensuring safety and reducing maintenance costs over its service life.