What are the Common Standards for Steel Grating in the market?

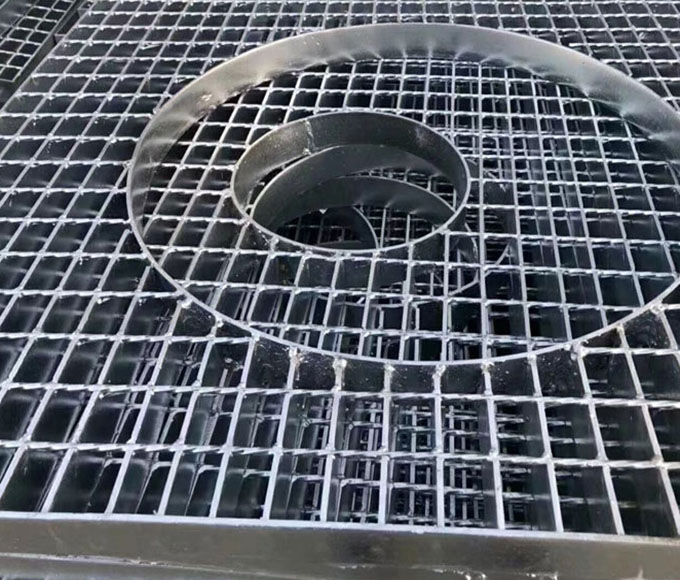

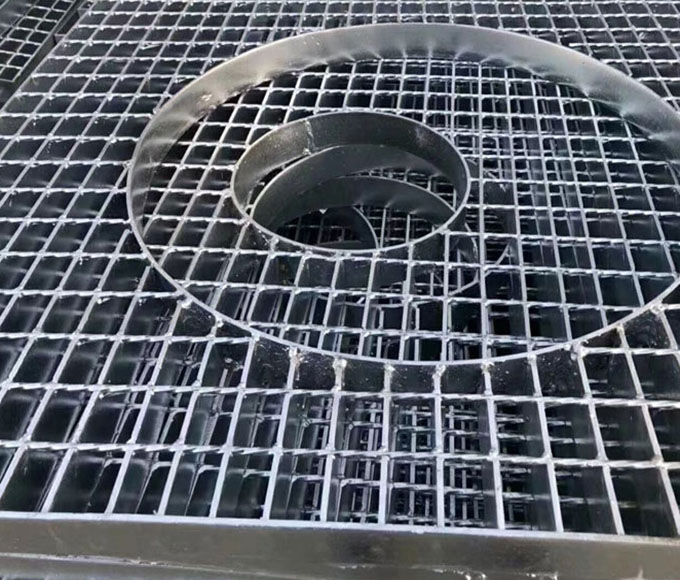

Steel grating, as a versatile structural material widely used in industrial platforms、walkways、 drainage covers and infrastructure projects, relies on uniform industry standards to ensure quality、safety and interoperability. These standards formulated by authoritative international and regional organizations, regulate every link from raw material selection and production processes to performance testing and application scenarios. For manufacturers、suppliers、engineers and buyers, grasping the common standards for steel grating in the global market is crucial to avoiding quality risks, meeting project requirements and facilitating cross-border trade. This article will dissect the core categories, key specifications, and practical significance of these mainstream standards.

1. Core Classification of Steel Grating Standards

Steel grating standards in the market are mainly divided into two categories: international universal standards and regional specialized standards. The former aims to unify technical requirements across borders, while the latter is tailored to local climate conditions, engineering needs, and industrial characteristics. This dual-system pattern ensures both global compatibility and regional adaptability, covering the majority of application scenarios in the steel grating industry.

2. Mainstream International and Regional Standards

2.1 International and American Standards

In North America and many international projects, the ANSI/NAAMM MBG 531-88 standard is recognized as the benchmark for steel grating. Developed by the American National Standards Institute (ANSI) and the National Association of Architectural Metal Manufacturers (NAAMM), this standard specifies strict requirements for carbon steel and stainless steel grating, including material grades, dimensional tolerances, weld strength, and surface treatment. For example, it mandates that carbon steel grating adopt ASTM A36 steel for bearing bars, with a minimum tensile strength of 400 MPa, and requires hot-dip galvanizing to comply with ASTM A123, ensuring a zinc coating thickness of at least 65 μm to resist corrosion. Additionally, the ASTM F1646 standard supplements specifications for slip-resistant steel grating, which is widely used in high-risk areas such as oil refineries and offshore platforms.

2.2 European Standards

Europe's steel grating standards are dominated by BS 4592-1987 (British Standard) and the updated EN 10048 (European Norm). BS 4592-1987 focuses on the design and production of mild steel grating, defining common bearing bar pitches (30mm, 40mm, 60mm) and cross rod spacings (50mm, 100mm), as well as load deflection limits—stipulating that the maximum deflection under design load shall not exceed 1/360 of the span. EN 10048, as a unified European standard, aligns material requirements for stainless steel grating, specifying that 304 and 316 stainless steel grades must meet minimum yield strength of 205 MPa and tensile strength of 515 MPa, making it suitable for corrosive environments such as chemical plants and coastal projects.

2.3 Asian Standards

In Asia, China's YB/T 4001-2007 (National Standard of the People's Republic of China) is widely adopted in domestic projects and cross-border trade with neighboring countries. This standard covers welded steel grating, press-locked steel grating, and serrated steel grating, matching material standards such as GB 700 for carbon steel and GB/T 13912 for hot-dip galvanizing. It emphasizes structural stability, requiring that the weld shear strength between bearing bars and cross rods shall not be less than 30 kN/m. Japan’s JIS G 3101 and South Korea’s KS D 3503 are also regional standards with similar core requirements, focusing on precision manufacturing and durability in high-humidity environments.

2.4 Specialized Standards for Stainless Steel Grating

For stainless steel grating, a high-performance variant used in corrosive and hygienic scenarios, there are specialized standards supplementing general specifications. The ASTM A480/A480M standard defines the flatness, thickness tolerance, and surface finish of stainless steel plates used in grating, while EN 10088-1 classifies stainless steel grades (304, 316, 2205 duplex) and their chemical compositions, ensuring corrosion resistance in specific environments. For example, 316 stainless steel grating must contain at least 2.0% molybdenum to resist pitting corrosion in marine and chemical applications, a requirement explicitly stated in these standards.

3. The Practical Value of Complying with Standards

Adhering to common steel grating standards is not only a regulatory requirement but also a guarantee for project safety and long-term operation. For manufacturers, compliance ensures production consistency and market access—non-compliant products may be rejected in international trade or lead to project accidents. For buyers and engineers, standard-compliant steel grating reduces the risk of structural failure, as it has undergone rigorous testing for load-bearing capacity, corrosion resistance, and durability. In cross-border projects, aligning with international standards avoids compatibility issues between components、simplifying procurement and construction processes.

4. Trends in Steel Grating Standards

With the development of green manufacturing and intelligent construction, steel grating standards are evolving towards higher environmental protection and performance requirements. Many regions are updating standards to promote low-carbon production processes, such as reducing zinc consumption in galvanizing while maintaining corrosion resistance. Additionally, the integration of digital technologies has led to new specifications for traceability—requiring manufacturers to label products with standard compliance information and production batch data, enabling full-life-cycle management of steel grating in projects.

Conclusion

The common standards for steel grating in the market form a comprehensive system covering international universality, regional adaptability, and specialized scenarios, with ANSI/NAAMM, BS/EN, and YB/T as the core frameworks. These standards regulate material selection, production processes, performance indicators, and application requirements, ensuring the safety, reliability, and interoperability of steel grating across industries and regions. For all stakeholders in the supply chain, understanding and complying with these standards is essential to navigating the global market, optimizing project quality, and promoting the sustainable development of the steel grating industry. As engineering technologies advance, these standards will continue to be updated and improved, adapting to new application scenarios and market demands.